Ring Main Compressed Air Distribution System

Push pipe into fitting 3.

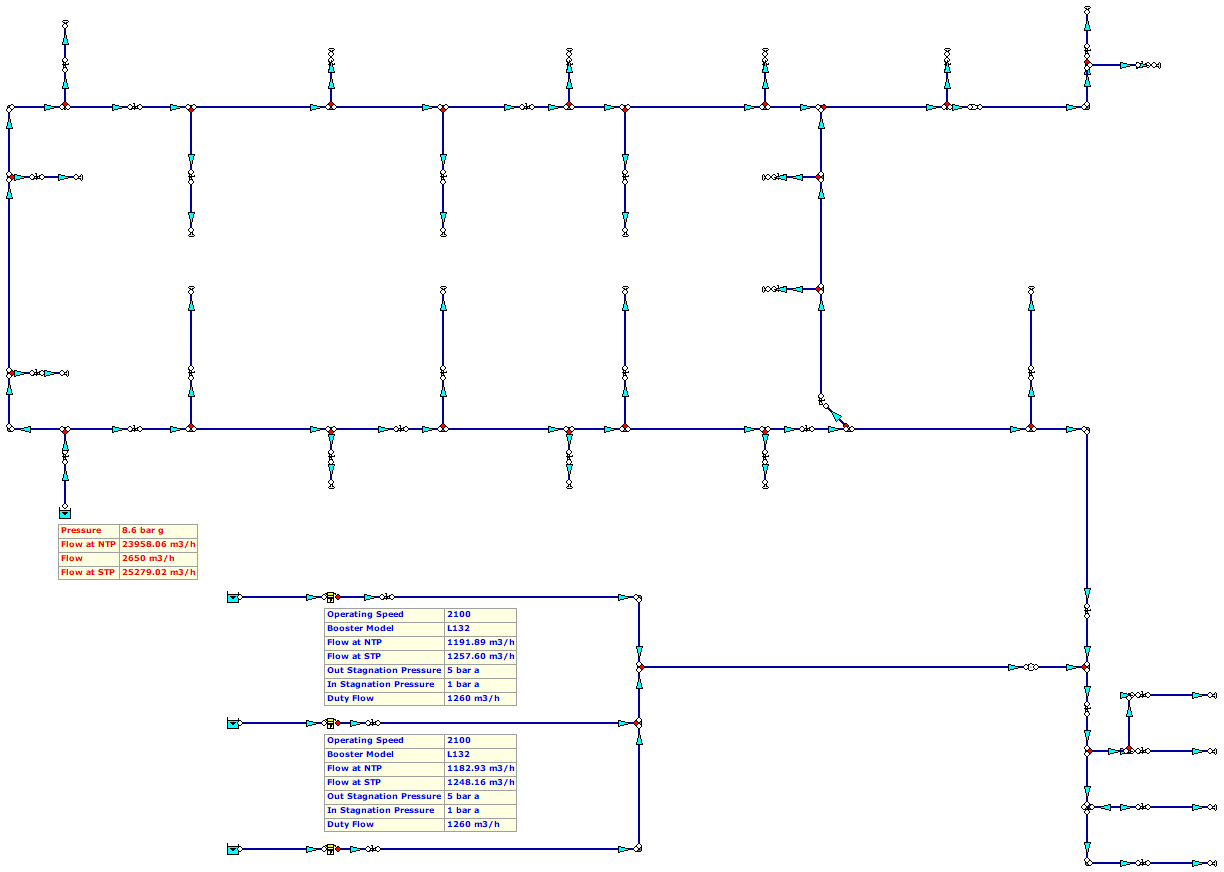

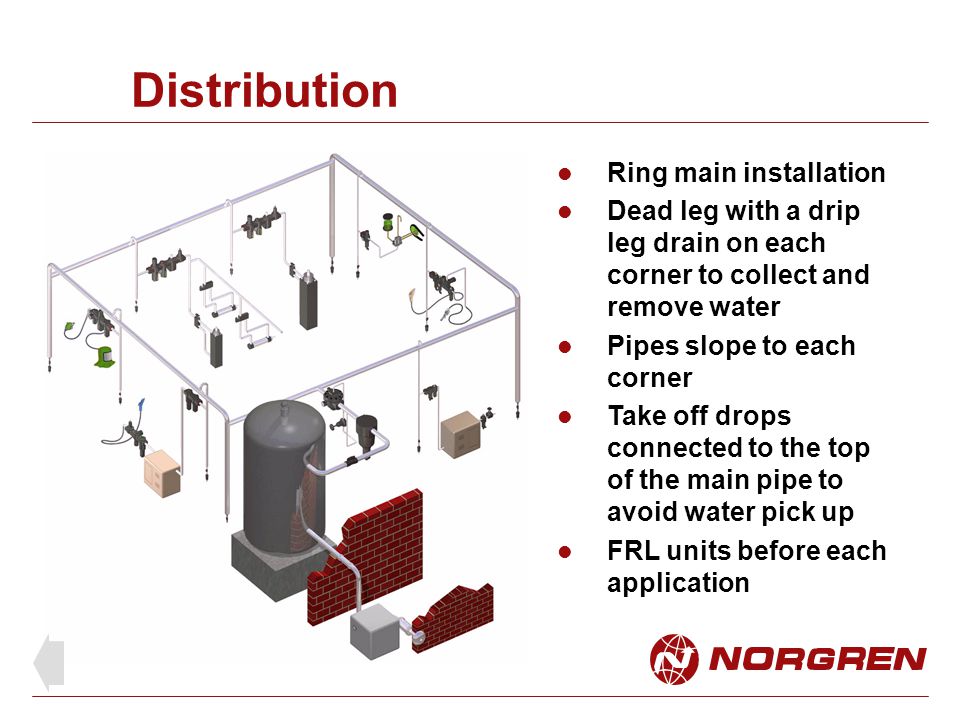

Ring main compressed air distribution system. The connection lines to points of use will therefore have to be larger than for a compressed air ring main. System complete in 2 days 1. The risers transport the compressed air from the compressors to the consumption zones the distribution pies split the air across the distribution zone and the service pipes route the air from the. Inadequate compressed air distribution systems will lead to high energy bills low productivity and poor air tool performance three demands are placed on a compressed air distribution system.

Compressed air piping system can generally be grouped into four main parts. This distribution method creates an increased distance from the main compressed air supply. Complex systems easy to achieve the pirtek range of push in fittings and pipes provide the ideal connection from compressor receiver to air line service components through to complete ring main and take off points. Compressed air ring main or distribution network.

Compressed air distribution network a compressed air distribution network is often the perfect solution for companies with large facilities. A compressed air system can be installed quickly and easily compared with other installation methods time savings of at least 50 are easily achievable. A distribution network system has a very similar design to a ring main system but it includes additional longitudinal and cross connections. A dead end main has the advantage of distributing the compressed air over the shortest possible run reducing pressure drop and economising on pipe cost.

Cut pipe square 2. Piping systems more than five years old have been shown to exhibit leaks of up to 25 percent yet many facilities are slow to upgrade equipment to the latest technology. A compressed air. The cost of installing larger pipe dimensions as well as fittings than those initially required is low compared to the cost of rebuilding the distribution system at a later date.

The new water trap tee solves the on going problem of moisture in a ring main system and provides an easy alternative to the need to install swan necks the ingenious inside arrangement of the fitting allows air to flow with minimum head loss from the main to the take off point without allowing water to follow. Inefficient compressed air distribution systems result in higher energy bills lower productivity and poor air tool performance. These three demands primarily apply to the main pipes and to the planned compressed air consumption for current needs as well as for the future. Compressed air distribution mains systems alternatives available are a dead end main or a ring main.

Its chief disadvantage is its lack of flexibility although the service supplied by a. The ideal connection from compressor receiver to air line service components through to complete ring main and take off points. A low pressure drop between the compressor and point of consumption a minimum of leakage from the distribution piping and efficient condensate separation if a compressed air dryer is not installed.